,

Industrial dishwasher machine

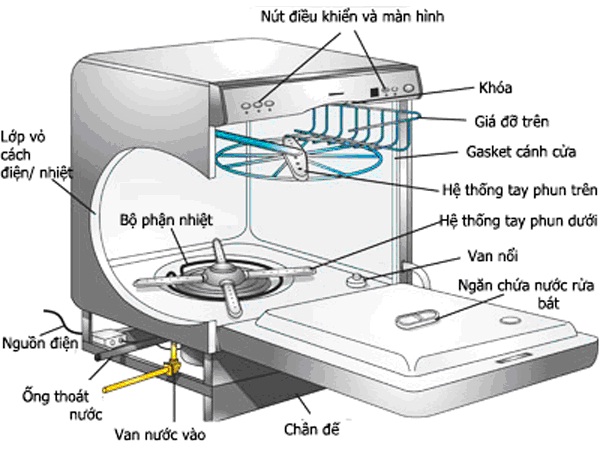

Construction of industrial dishwashers

1. The inside of the dishwasher

Although dishwasher watertight, but they do not really filled with water. Only at the bottom of the basin is filled with water. Here, the elements heat up to 130 degrees hot water F (55 degrees C), sometimes 140 degrees F (60 degrees C). Then, a pump to push water sprinkler systems. Here, water is sprayed onto the surface strongly dirty dishes. Let's think of the pipes in the garden without nozzles - if you put your thumb over the mouth tube, reduces space drainage water, and therefore more powerful water jet. Parts of the dishwasher nozzle acts exactly this principle. Strong spray of water as well as rotating spray arm, like grass sprayed automatic faucets that do or see in the park.

After spraying the exhaust cleaning process, the water sinks to the bottom of the exit, where the pump will push the water out. Depending on the type of dishwasher, waste water will go directly into the pipes under the sink, or go through the pipes in the tank of the machine.

The final step in the wash cycle is drying cycle. Heat the bottom parts of the machine will heat the air flow inside help dry dishes. To save power some people do not use dishwashing cycle nay.May not too complicated machinery.

Basic Structure of industrial dishwasher machine

2. Control System

The control system is placed inside the machine door just below the control panel. Many of the dishwasher control system using simple: determine the cycle time for how long and activate functions such as flushing detergent, spray wash, rinse ... in time appropriate. The expensive machine control system by computer. The modern machinery required to latch the new machine to operate, it is safe to have a child.

3. Van loaded

Intake valve where the water is led directly to the machine. Pumping of water into the pump intake is not potted plant that when the intake valve opens, water pressure pushes water into the machine.

4. Pump

An electric motor assist pump operation. During the pumping cycle, the pump will push the water into the spray arm. In the draining cycle, pump discharge directly into the drain pipe. Motor pump unit is mounted at the bottom of the pot, in the middle of the machine.

There are two main types of pumps:

Inverse pump: This pump pumps water to the spray arm and pump out waste water by changing the direction of the motor. The reversible pump is usually mounted vertically.

Pumps Direct: motor running in one direction, so the direction of flow is transferred from the spray arm to the outlet by electric solenoid wire loop - loop wire allows the valve to open and close the device or switch tube lead pipes connected to the other. Inverse pump is usually mounted horizontally.

Dishwasher can be installed in the form of mobile or fixed. For this type of machine can be moved, on the can be used as a counter. When not in use, the machine can be defined in the wall. When operating the machine, thanks to the small wheel you can push the machine to sink in that the machine is connected to the tap and plug outlet nearby. For stationary machines, the machine is mounted under a cabinet and bolts available. The pipes under the sink directly connected to the hot water pipe and drain pipe, fixed machines are usually plugged in under the sink. Both these techniques require 120V power line.